Lắp ráp tự động hóa

NVY provide professional robot assembly line solutions, mainly using industrial assembly robots or collaborative assembly robots. We provide world-renowned robot brands including: FANUC, ABB, KUKA, etc.

Assembly industries we are involved in include automobile assembly lines, home appliance assembly lines, electromechanical assembly lines, electronic assembly lines, etc. such as PCB assembly solutions

Automation Assembly Robots by Brand

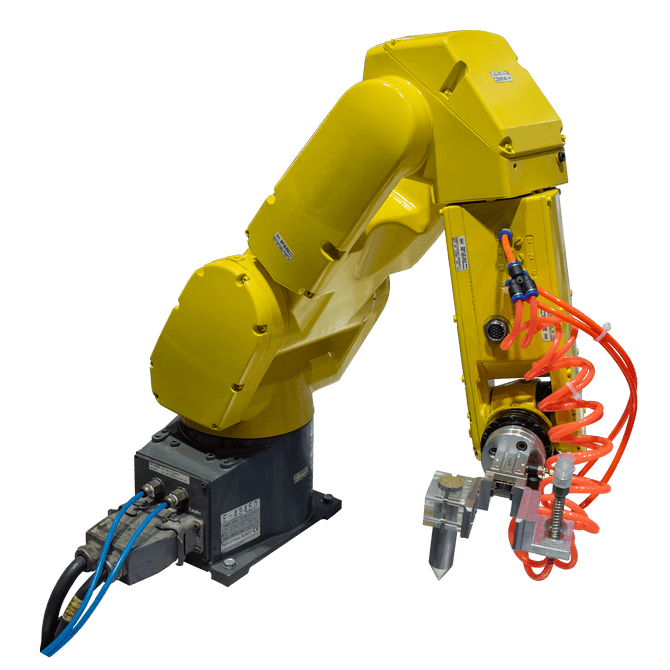

FANUC Robotic Assembly

FANUC robots are known for their high-precision control systems, which can ensure precise docking and installation during the assembly process and improve assembly quality. Its CNC system is powerful, making the robot’s motion control more stable and reliable.

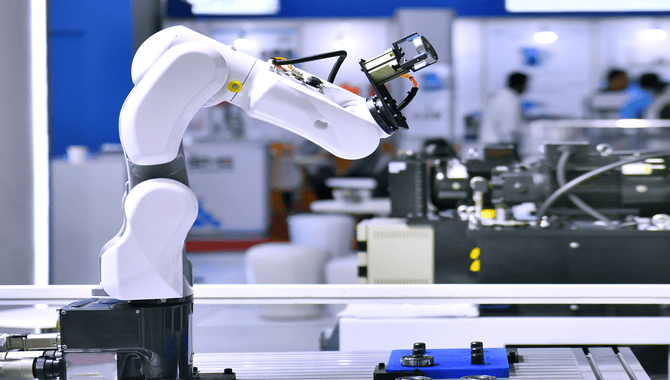

KUKA Robot Assembly

KUKA robots have fast movement speed and short action cycle time, and can complete a large number of assembly tasks in a short time. This high efficiency significantly improves production efficiency and capacity.

ABB Robot Assembly

ABB assembly robots are famous for their high precision and stability,and some robots have been running on the market for more than ten years without any major problems, which fully demonstrates their excellent stability and reliability.

Advantages of Automation Assembly

Khả năng thích ứng

Automation assembly robots have a modular design, allowing components to be easily replaced to accommodate new production tasks or product requirements

Chất lượng

Automation assembly robots perform tasks with high consistency, achieving the same precision and results each time, reducing product-to-product variations

Hiệu quả

Automation assembly robots can perform repetitive tasks with extremely high speed and precision. This efficiency can significantly shorten the production cycle

Tiết kiệm

By precisely controlling material usage and reducing reject rates,automation assembly robots help reduce waste of raw materials and scrap

Key Elements of Robotic Assembly Design

- Robot selection: Select the appropriate robot model and specifications according to the needs of the assembly task to ensure that the robot's performance meets the requirements.

- Tooling design: Design reasonable tooling fixtures and positioning devices to ensure the stability and accuracy of parts during the assembly process.

- Sensor configuration: Configure necessary sensors and detection devices to monitor various parameters and states during the assembly process in real time.

- Control algorithm: Develop an efficient control algorithm to ensure the stability and accuracy of the robot when performing assembly tasks.

Automation Assembly for Different Industry

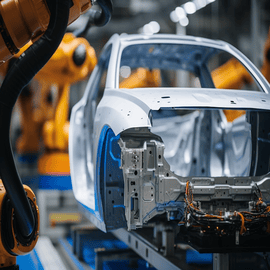

Automotive Assembly Robots

| Assembly robots can complete various assembly tasks in automobile manufacturing at high speed and precision, such as tightening bolts and nuts, assembling parts, etc. They are widely used in assembly lines of automobile bodies, chassis, engines and other parts to improve production efficiency and product quality. |

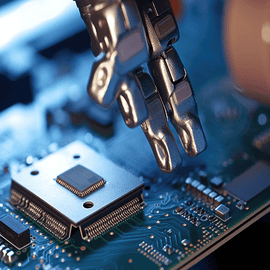

Electronic Assembly Robots

In the field of electronic product manufacturing, assembly robots are not limited to assembling PCBAs, but can also complete the assembly of mobile phones, computers, tablets and other devices. These robots can handle delicate electronic components to ensure product consistency and quality stability.

Home Appliance Assembly Robots

Assembly robots also play an important role in the assembly process of household appliances such as televisions, refrigerators, washing machines, etc. They can complete the assembly and debugging of various parts and components, improving production efficiency and product reliability.

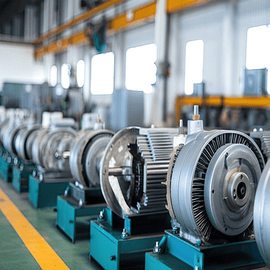

Electromechanical Product Assembly Robots

Assembly robots can also be used in the assembly of various electromechanical products and their components, such as small motors, pumps, valves, etc. They can complete the assembly and testing of these products and improve the degree of automation of the production line.

Bạn có cần một

Thiết kế mới?

Kiểm tra các tùy chọn và dịch vụ của chúng tôi

Nhận báo giá

Nhập thông tin cá nhân của bạn dưới đây và hãy để bắt đầu nói về dự án mới của bạn.